Discussing how to save more fuel for small excavators has always been a problem that can not be ignored, I used to organize a lot of ways, now come to the system to look at.

Small-scale road rollers mainly refer to compaction machines of more than 3 tons and less than 10 tons.

The principles to be followed when inspecting, draining and refueling the transmission components of a small roller

The use of hydraulic oil for small rollers is a very important part of the whole machine, but there are still many friends who don’t know much about the use of hydraulic oil.

The simple way is to clean, you can prepare a small air compressor. The fuel is released during the cleaning process, but be careful not to let it separate and leave some fuel.

If your excavator often uses a crusher, the reason for the blackening of hydraulic oil is not only impurities, but also the irregularity of the grease.

Road rollers are favored by the majority of engineering projects due to their convenient operation, flexibility, high efficiency, wide application and low price. Walk-behind rollers are widely used fo

1. Read the manual of the excavator in detail, the working principle, operating procedures, maintenance and use requirements of the excavator hydraulic system.

1. Purge method. That is, part of the diesel is stored in the fuel tank, and then the compressed air of 19.6~29.4KPa is passed into the bottom of the fuel tank with a plastic pipe, so that the diesel

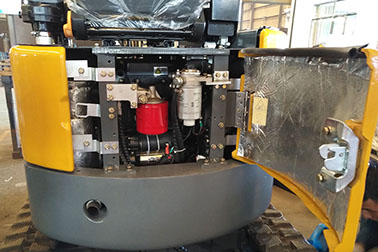

Diesel oil: 0# ; Hydraulic oil: 46# ; Diesel Engine oil: SAE15W-40